FeRFA Award Winning Project 2016

Brief Description

This advanced aerospace manufacturing, research, and development facility has brought together two existing aging facilities into one brand new state of the art building.

The facility produces engine control systems for a range of applications, including the Rolls-Royce Trent family of aircraft engines.

Problems and Requirements

The original concrete substrate required repair following the removal of old coal deposits which had contaminated the area over time.

12,000 cores were cut out and then filled with EP Screed mortar. A total of 9500m2 of Remmers resin flooring was installed.

The flooring needed to fulfil the Clients high standards and requirements which consisted of:

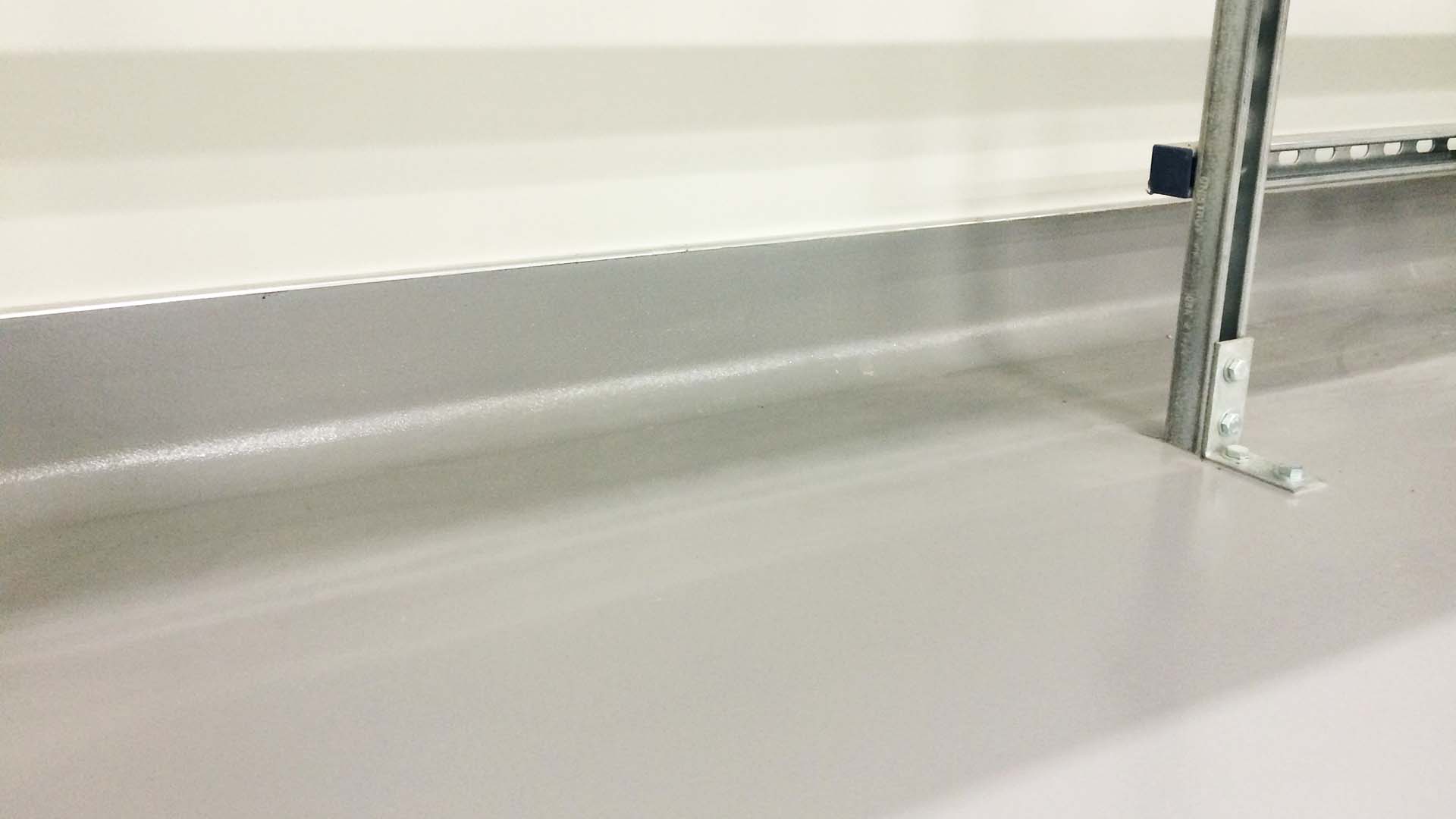

- 420m2 of Chemical Resistant Flooring with 1.1m high Chemical Resistant Wall Render

- 590m2 of Epoxy Conductive Flooring System with an Anti-Slip Textured Finish

- 8490m2 of Remmers Self Smoothing Epoxy Resin with a Slip Resistant Seal Coat.

To complement the floors 3500m (2.1 miles) of Remmers Epoxy Cove Skirting were also installed.