Highly chemical resistant resin coating for new power station

Brief Description

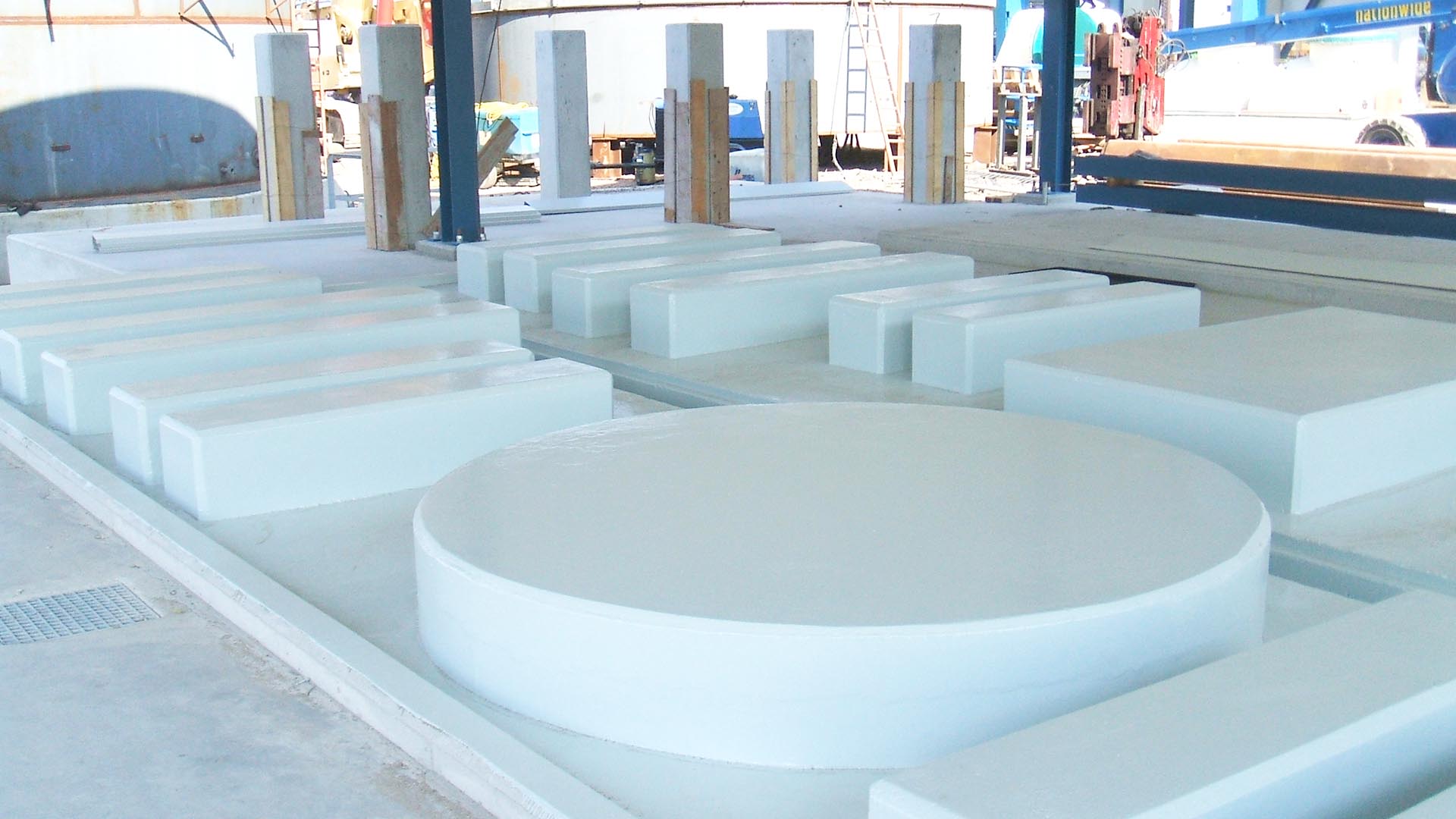

For a new power station, the water treatment plant room where sulphuric acid and sodium hydroxide is stored and used required treating with a novolac epoxy resin coating system to meet the clients exacting specification.

Problems and Requirements

Newly cast concrete required protective coatings to resist the strong acid (98% H2SO4) and alkali (45% NaOH) in the water treatment plant.

The coating needed to be installed prior to the plant being lowered into place. This meant that the system had to be installed with no weather protection to the building.

The system selected comprised of Epoxy MT100 as a damp tolerant epoxy primer followed by three coats of Epoxy CR: a highly resistant novolac epoxy.

To ensure that no pinholes (areas of weakness) existed, the surface was Holliday (spark) tested to identify pinholes, which were then filled before over coating with the final coat of Epoxy CR.