Specialist flooring for the electronics industry

Brief Description

Problems and Requirements

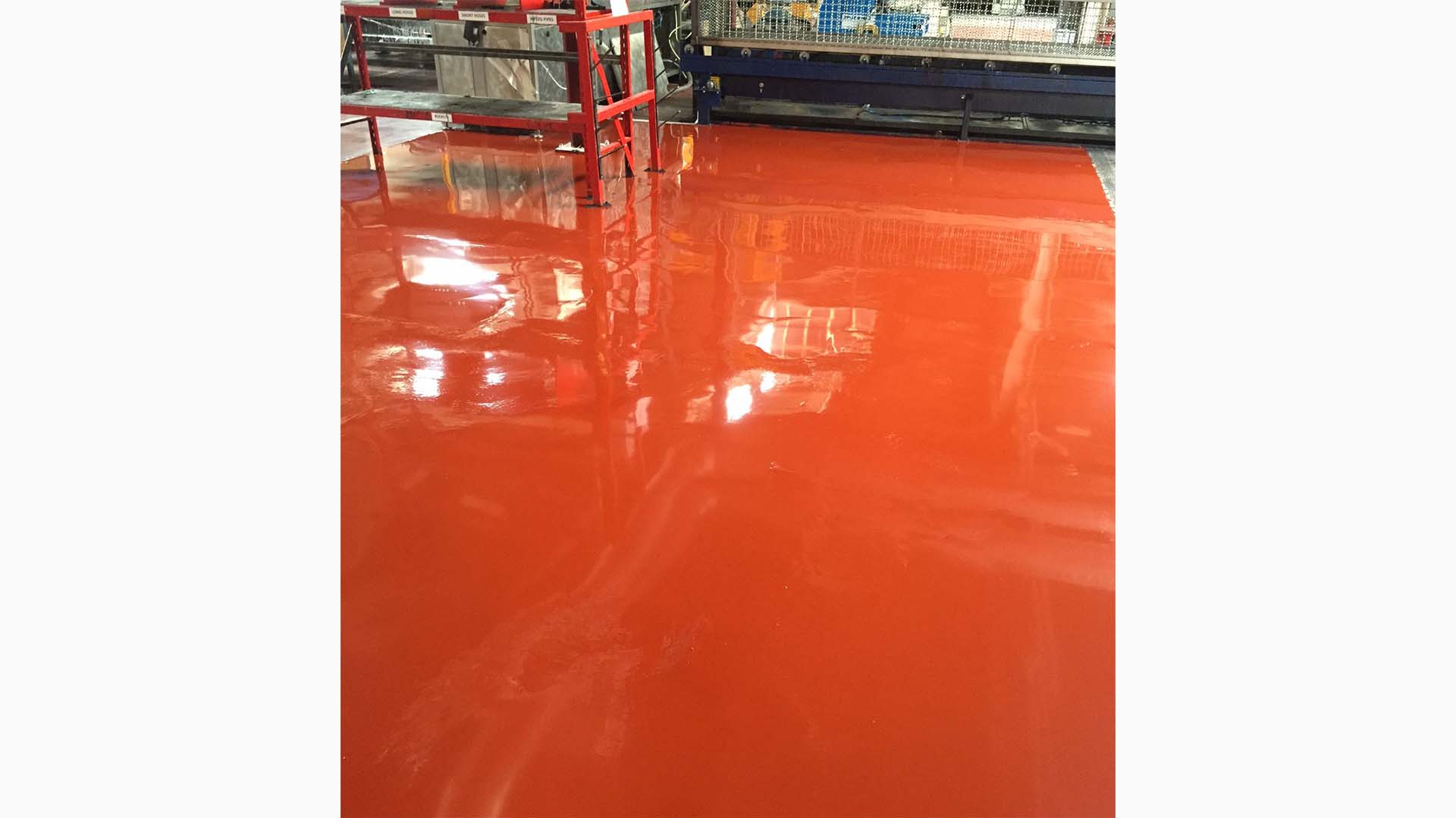

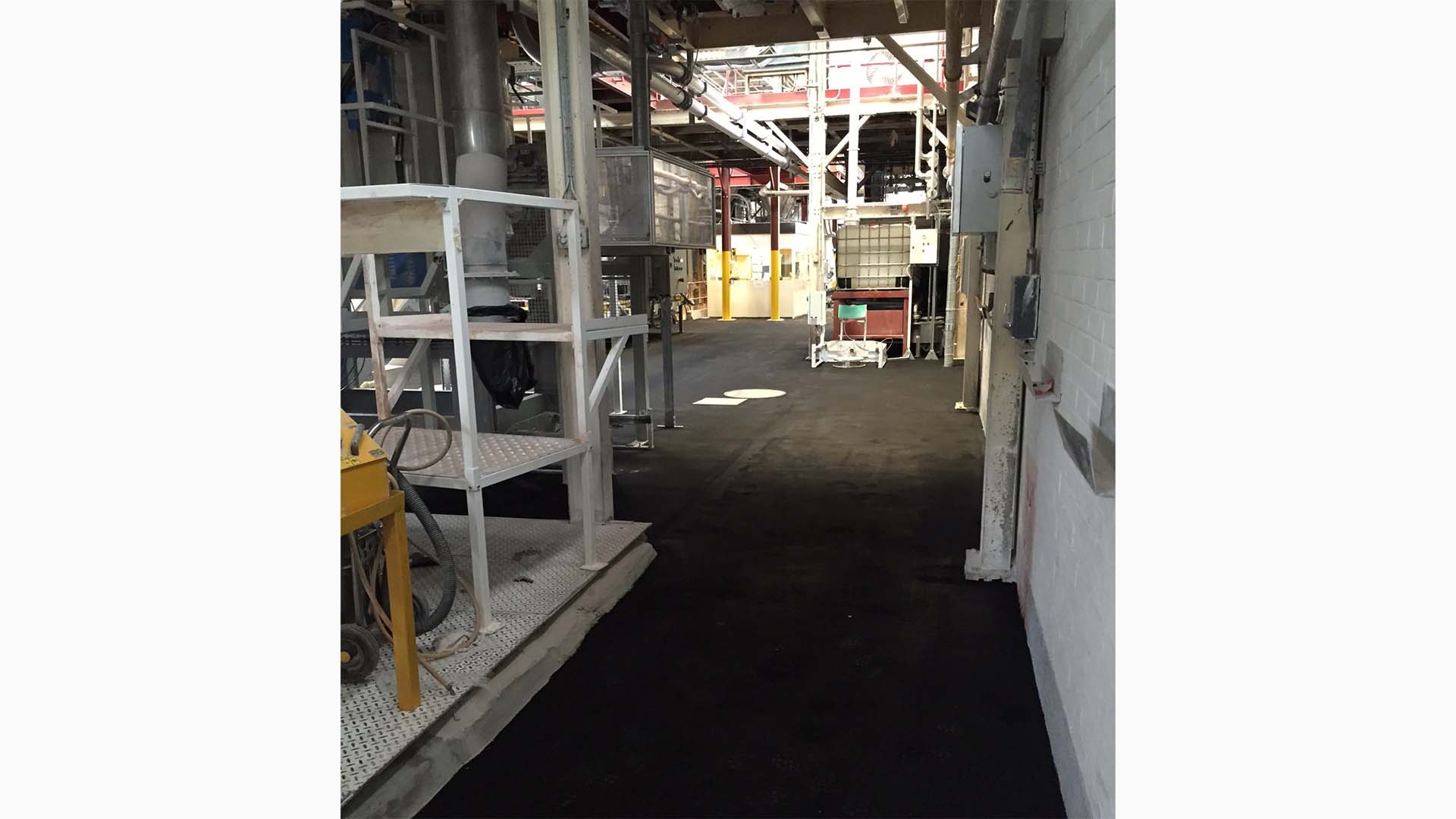

The surface had cracks which needed to be repaired and reinforced prior to the anti-static system being applied. The first production area required a hard wearing anti-static system and the second required a hard wearing chemically resistant floor.

Due to the nature of the products being manufactured in these areas, it was vital that the installed systems met EN1081 standard and achieved an earth leakage resistance of >1 x 106 .

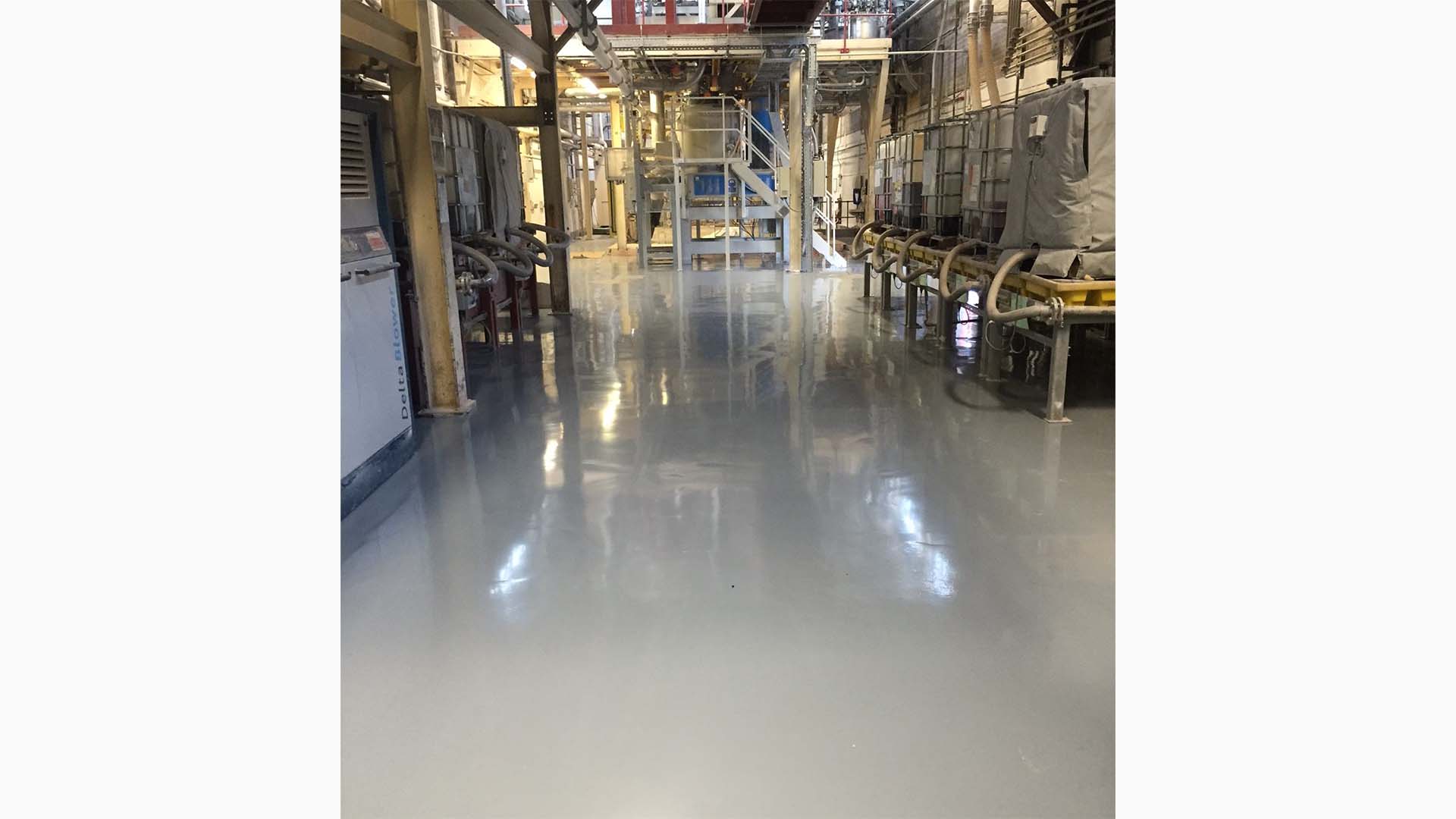

In the first production area Remmers Epoxy AS system was selected. The floor required initial repairs due to cracking in the mezzanine substrate.

A fibre glass reinforcement was incorporated into the specialist Remmers epoxy priming system. This was used to bridge the gaps so that they would not reflect through the Remmers conductive resin flooring system Remmers WHG AS resin system was chosen for the 2nd production area as it has very good chemical resistance qualities as well as being able to provide a conductive floor of >1 x 106.